Top Industrial Meat Grinder Models for Efficient Food Processing?

In the realm of food processing, selecting the right equipment is crucial. Experts emphasize this, including Howard Smith, a leading figure in the industrial meat grinder industry. He once stated, “The efficiency of an industrial meat grinder can significantly impact productivity.”

Industrial meat grinders vary widely in capability and design. Some models are robust, able to handle large volumes, while others are more compact yet effective. Each model caters to different needs. Choosing the right one requires careful thought and analysis.

Not all grinders perform equally, and some may fall short of expectations. Evaluating the performance and durability of these machines is essential. Reliable models can enhance your production line. However, it's important to remember that even top models may require maintenance over time. Reflection on their performance is key to ensuring operational efficiency.

Overview of Industrial Meat Grinders and Their Importance

Industrial meat grinders play a crucial role in food processing. They enable efficient, consistent grinding of meat for various applications. According to industry reports, the $13 billion meat processing equipment market is expected to reach by 2026, reflecting a growing demand for high-quality machines. With advancements in technology, modern grinders improve productivity significantly.

In food production, hygiene and efficiency are paramount. The design of industrial meat grinders focuses on these aspects. They allow for quick cleaning and minimal downtime. Yet, improper use can lead to contamination. Operators must be trained thoroughly.

Tips: Regular maintenance is essential. Check the grinder’s blades frequently. Ensure they are sharp and in good condition. Neglect can lead to uneven grinding and wasted product. Also, consider the power capacity of the grinder. High-capacity models can process larger volumes, but they also require proper handling. Balancing capacity with actual needs can optimize production.

Key Features to Look for in Industrial Meat Grinder Models

When selecting an industrial meat grinder, several key features should be prioritized. Efficiency is crucial, as the processing speed can greatly affect production. Models that feature high horsepower motors can grind meat faster. Reports indicate that grinders with at least a 3 HP motor can produce up to 1,500 pounds of meat per hour.

Another important feature is the construction material. Stainless steel is preferred for its durability and ease of cleaning. Grinders made of aluminum or plastic may not withstand heavy use. A focus on quality materials can reduce maintenance costs over time, but initial investment can be higher.

Size and capacity also play a significant role. Knowing the volume of meat to process daily helps in choosing the right model. Some establishments may find that a 32 mm grinder fits their needs best. However, larger models are available for high-demand operations but come with additional space requirements. Ultimately, the choice depends not only on specifications but also on practical considerations like space and budget.

Comparative Analysis of Top Industrial Meat Grinder Brands

When choosing an industrial meat grinder, brands offer varying features and capabilities. Each model has its strengths and weaknesses. Comparing them can help identify the best fit for food processing needs. Some grinders have high capacity but may sacrifice power efficiency. Others focus on precision but might struggle with larger batches.

Efficiency is not just about speed. It’s also about consistency in grinding. Some grinders produce uneven textures, leading to unsatisfactory results. It's essential to evaluate the ease of cleaning and maintenance as well. A complex design may hinder regular upkeep, impacting long-term performance.

User reviews provide valuable insights. They often highlight usability issues that specs do not cover. We all want reliable equipment that stands the test of time. However, unreliable performance can lead to frustration. Understanding these nuances helps in making informed decisions. A methodical comparison can lead to better choices in this critical area of food processing.

Top Industrial Meat Grinder Models for Efficient Food Processing

| Model | Power (HP) | Capacity (lbs/hr) | Grinding Plates | Features |

|---|---|---|---|---|

| Model A | 5 | 800 | 3 | Stainless Steel, Easy Clean |

| Model B | 7.5 | 1200 | 4 | High Efficiency, Safety Guard |

| Model C | 10 | 1500 | 5 | Variable Speed, Digital Control |

| Model D | 15 | 2000 | 6 | Auto Shut-off, Easy Maintenance |

Performance Factors Affecting Efficiency in Food Processing

When it comes to industrial meat grinders, efficiency is key. Performance factors play a vital role in the food processing industry. According to a recent industry report, operational efficiency can determine the overall productivity of a facility. High-capacity grinders prioritize speed, meaning they can process more meat in less time. The processing speed can range widely, from 500 to over 2000 pounds per hour, depending on the model.

One crucial factor is power. Grinders with higher power ratings can handle tougher meats. This capability prevents jams and reduces downtime. Another significant element is design. Machines with a streamlined feed can minimize waste. It’s essential to consider whether the equipment supports various attachments for different processing tasks.

Tips: Regular maintenance is vital. Clean the grinder after each use. Check parts for wear and tear monthly. Operators should receive thorough training to maximize productivity. Consider cycle times. Sometimes, slower cycles can yield better meat quality. Discuss efficiency with your team to identify areas for improvement.

Top Industrial Meat Grinder Models for Efficient Food Processing

Maintenance Tips for Prolonging the Life of Meat Grinders

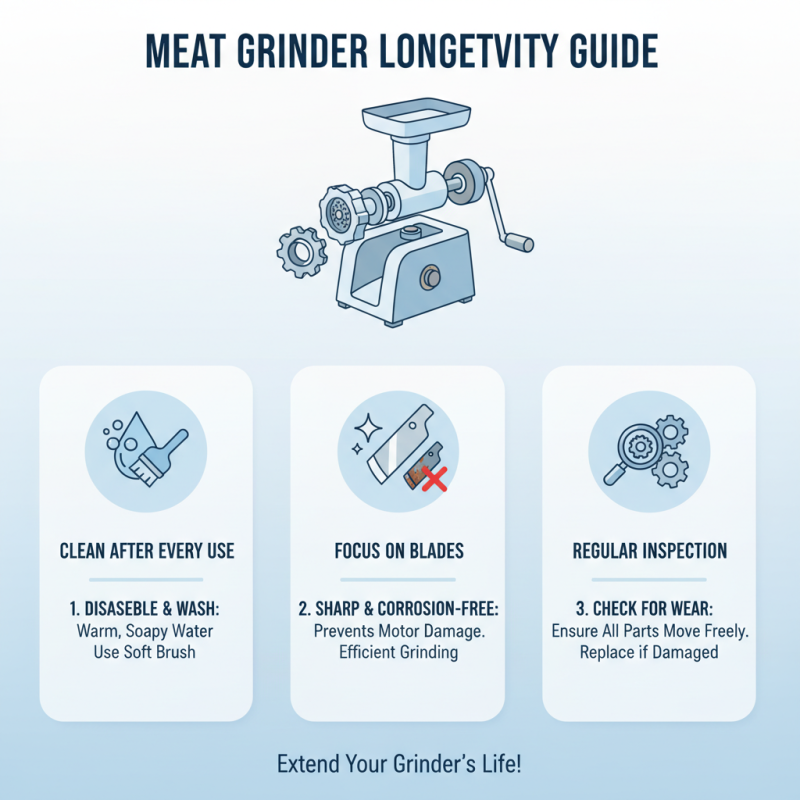

Proper maintenance is crucial for extending the life of your meat grinder. Regular cleaning is essential. After each use, disassemble the grinder and wash all parts with warm, soapy water. Use a soft brush to remove any stubborn meat residues. Pay attention to the blades; ensure they are sharp and free from corrosion. Dull blades can lead to inefficient grinding and could damage the motor over time.

Lubrication is often overlooked. Apply food-grade lubricant to the moving parts occasionally. This helps reduce friction and wear on the components. It's also a good idea to check for loose screws or bolts regularly. Tightening them can prevent mechanical issues that may arise from vibrations during operation. Ignoring these small tasks can result in performance decline.

Storage conditions matter, too. Keep the grinder in a dry place, away from moisture. Exposure to harsh environments can lead to rust. Consider using a cover to protect it from dust. Remember, neglect can lead to costly repairs or replacements. Regular, attentive care is the key to longevity.

Related Posts

-

Top 10 Commercial Meat Blenders for Perfectly Ground Meat Every Time

-

How to Choose the Best Commercial Meat Grinder for Your Business Needs

-

How to Choose the Best Industrial Food Grinder Machine for Your Business

-

Best 10 Industrial Meat Grinders for Efficient Meat Processing

-

2026 Best Commercial Meat Grinder Options for Home and Business Use?

-

What is Dog Food Manufacturing Equipment? Essential Tools for Pet Food Production