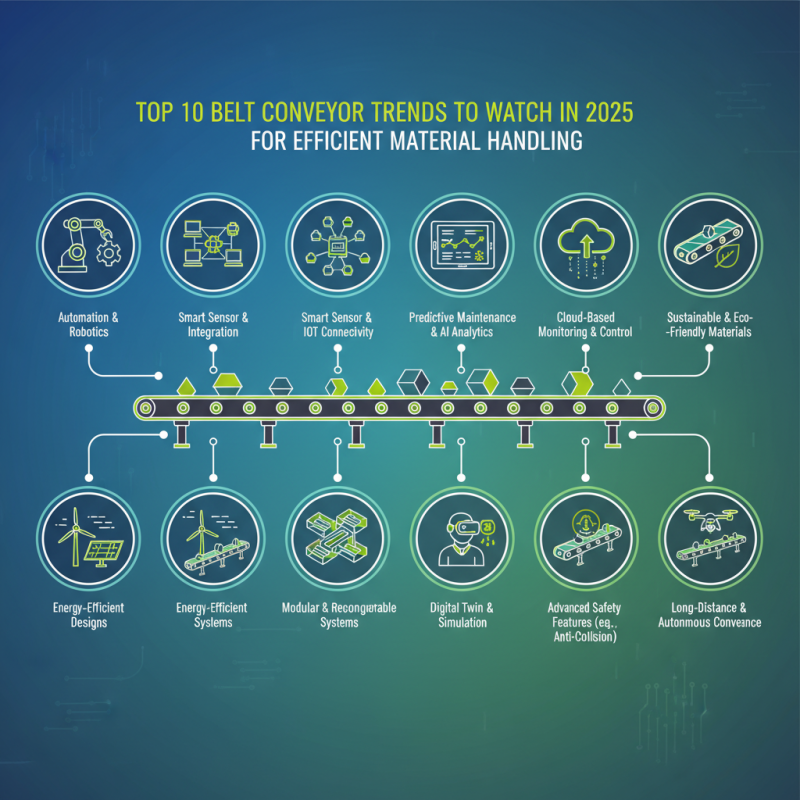

Top 10 Belt Conveyors Trends to Watch in 2025 for Efficient Material Handling

As we look ahead to 2025, the evolution of belt conveyors presents exciting opportunities for enhancing efficiency in material handling across various industries. With increasing demands for streamlined operations and innovative solutions, the trends shaping belt conveyors are pivotal for businesses aiming to optimize their logistics and supply chain processes. From advancements in automation to the integration of smart technologies, the future of belt conveyors promises to revolutionize how materials are transported and managed within facilities.

The focus on sustainability and energy efficiency is also set to redefine the landscape of belt conveyors in the coming years. Companies are increasingly recognizing the importance of minimizing their environmental impact while maintaining operational effectiveness. Innovations in materials and design will not only enhance performance but also contribute to a greener approach to material handling.

In this article, we will explore the top belt conveyor trends that are expected to make significant impacts in 2025. By understanding these trends, businesses can position themselves to harness the full potential of belt conveyors, ensuring they remain competitive in an ever-evolving market.

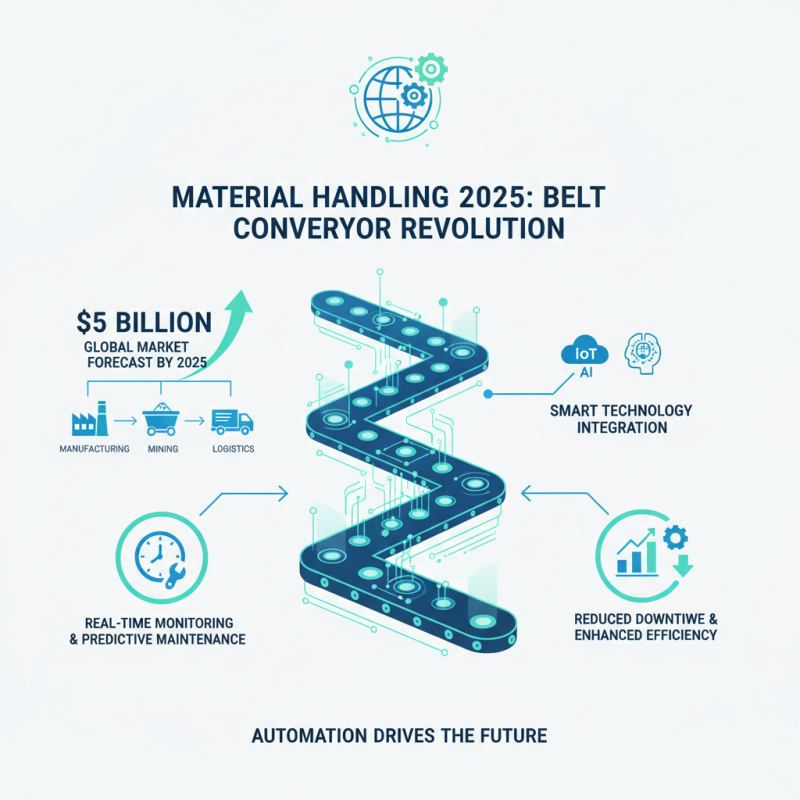

Emerging Innovations in Belt Conveyor Technology for 2025

In 2025, the landscape of material handling is set to revolutionize with the emergence of cutting-edge innovations in belt conveyor technology. Industry reports forecast that the global belt conveyor systems market will reach approximately $5 billion by 2025, driven by increasing demand for automation in various sectors including manufacturing, mining, and logistics. The integration of smart technologies, such as IoT and AI, into conveyor systems is a significant trend, enabling real-time monitoring and predictive maintenance. This advancement helps reduce downtime and enhances operational efficiency, as businesses can proactively address potential failures before they lead to costly interruptions.

Moreover, the development of eco-friendly conveyors is gaining traction, with a notable focus on sustainable materials and energy-efficient designs. According to a recent industry study, companies implementing energy-efficient belt conveyors can save up to 30% on operating costs. These systems often incorporate regenerative braking and energy recovery technologies, further promoting environmental sustainability. Additionally, advancements in modular conveyor design are allowing for greater flexibility and scalability, enabling businesses to optimize their material handling systems dynamically based on changing operational demands. As these trends continue to evolve, they promise to enhance both productivity and sustainability in material handling operations across various industries.

Integration of IoT and Automation in Material Handling Systems

The integration of IoT and automation in material handling systems is shaping the future of industry workflows. As noted in a market research report by Grand View Research, the global IoT in logistics market is expected to reach $35 billion by 2026, growing at a CAGR of 23.4%. This substantial growth underscores the increasing reliance on interconnected systems to streamline operations and enhance overall efficiency within material handling processes, particularly through belt conveyors.

Automation technologies, when coupled with IoT capabilities, facilitate real-time tracking of goods, predictive maintenance, and adaptive logistics solutions. Companies can leverage data analytics to optimize conveyor belt operations, minimizing downtime and ensuring seamless material flow. A study from McKinsey highlights that organizations implementing IoT solutions can experience a 10-30% reduction in operating costs. This trend signifies the potential of these technologies to drive profound operational improvements.

**Tips for Implementation:** To successfully integrate IoT and automation in material handling, businesses should consider starting with a phased approach. Initiate pilot projects to test IoT-driven sensors and monitoring tools on existing belt systems. Additionally, ensure a robust training program for staff to maximize the benefits of these technologies while cultivating a culture of data-driven decision-making. Engaging employees in this transition fosters greater acceptance and can lead to innovative solutions in routine processes.

Sustainability Trends: Eco-friendly Materials in Conveyor Design

The increasing emphasis on sustainability is transforming the conveyor design landscape, directing attention towards eco-friendly materials. As industries strive to minimize their environmental impact, the integration of renewable and recyclable materials in conveyor systems becomes paramount. Innovative approaches, such as using bioplastics or materials derived from sustainable sources, play a crucial role in reducing the carbon footprint of material handling processes. By prioritizing these materials, manufacturers can not only enhance their sustainability credentials but also meet the growing demand from consumers for greener solutions.

Moreover, the inclusion of energy-efficient technologies alongside eco-friendly materials is reshaping the future of belt conveyors. The design of conveyors is evolving to incorporate lightweight, durable materials, which not only decrease energy consumption but also prolong the lifespan of the equipment. Enhanced mechanical efficiencies and reduced operational costs are achievable through these advancements, further supporting sustainable practices in various industries.

As companies aim for more sustainable operations, the focus on eco-conscious materials in conveyor design will continue to drive innovation and efficiency in material handling solutions through 2025 and beyond.

Smart Monitoring Solutions: Enhancing Conveyor Efficiency with AI

As the industry progresses towards increased automation and efficiency, smart monitoring solutions are set to play a pivotal role in enhancing conveyor efficiency. By leveraging artificial intelligence (AI), these systems offer real-time analytics that monitor the performance of belt conveyors, identifying potential issues before they escalate into significant problems. This proactive approach not only minimizes downtime but also optimizes maintenance schedules, leading to reduced operational costs and improved productivity.

AI-driven smart monitoring solutions utilize advanced algorithms to analyze data collected from various sensors integrated into the conveyor systems. This data can track variables such as speed, load, wear and tear, and environmental conditions, providing operators with a comprehensive overview of the conveyor's health. With predictive analytics, businesses can make informed decisions about maintenance and upgrades, ensuring that their material handling processes remain efficient and reliable.

As the demand for smarter and more responsive systems grows, embracing these technologies will be crucial for manufacturers aiming to maintain a competitive edge in the ever-evolving landscape of material handling.

Increased Demand for Modular Conveyor Systems in Diverse Industries

The increasing demand for modular conveyor systems across various industries is shaping the future of material handling. As companies strive for greater efficiency and flexibility in their operations, modular conveyor systems provide an innovative solution that can be easily adapted to meet changing needs. These systems offer the ability to scale operations quickly, allowing businesses to respond to fluctuations in demand without the need for extensive overhauls of existing equipment. This adaptability is particularly crucial in sectors like retail, manufacturing, and logistics, where the ongoing shifts in consumer behavior and production requirements have become the norm.

Furthermore, modular conveyor systems are designed with sustainability in mind. With a focus on reducing waste and improving energy efficiency, these systems are increasingly being integrated with smart technologies that can monitor performance and optimize resource use. The ability to customize these conveyor systems not only enhances workflow but also supports sustainable practices within diverse industries. As businesses invest in modernizing their operations, the trend towards modular solutions is likely to gain momentum, offering a path toward enhanced operational efficiency and a reduced environmental footprint. This makes modular conveyor systems not just a trend, but a necessity for businesses looking to thrive in an ever-evolving marketplace.

Top 10 Belt Conveyors Trends to Watch in 2025 for Efficient Material Handling

| Trend | Description | Expected Impact |

|---|---|---|

| Modular Conveyor Systems | Increasing flexibility and adaptability in material handling systems. | Higher throughput and reduced downtime. |

| Automation Integration | Seamless integration of AI and robotics in conveyor systems. | Improved efficiency and reduced labor costs. |

| Sustainability Focus | Incorporating eco-friendly materials in conveyor construction. | Reduced environmental footprint and compliance with regulations. |

| Smart Sensors | Utilization of IoT sensors for real-time monitoring. | Enhanced operational oversight and predictive maintenance. |

| Predictive Maintenance | Using data analytics to anticipate equipment failures. | Minimized downtime and reduced maintenance costs. |

| Customizable Solutions | Tailoring conveyor designs to meet specific industry needs. | Increased customer satisfaction and operational flexibility. |

| Energy Efficiency | Developing conveyors that consume less power. | Lower operating costs and improved sustainability. |

| Advanced Materials | Utilizing lightweight and durable materials for belt construction. | Enhanced performance and longevity of conveyor systems. |

| Data Analytics | Employing data analysis for process optimization. | Better insights for strategic decisions and improvements. |

Related Posts

-

10 Essential Tips for Choosing the Right Conveyor Belt Conveyor for Your Business

-

Top 10 Belt Conveyor Design Tips for Efficient Material Handling

-

7 Best Metal Detectors for Conveyor Belts to Ensure Quality Control in 2023

-

How to Choose the Best Commercial Meat Grinder for Your Business Needs

-

Top Benefits of Using Steel Conveyor Belts in Industrial Applications

-

What is Dog Food Manufacturing Equipment? Essential Tools for Pet Food Production