2025 How to Choose the Best Stainless Steel Conveyors for Your Business

In the fast-evolving landscape of industrial operations, choosing the right equipment is crucial for efficiency and productivity. Among the various options available, stainless steel conveyors have emerged as a preferred choice in multiple sectors, including food and beverage, pharmaceutical, and packaging industries. According to a recent report by Industry Research Analysts, the global stainless steel conveyor market is expected to grow at a CAGR of 7.2% from 2023 to 2028, driven by advancements in technology and rising demand for hygienic and durable handling solutions.

Industry expert Dr. James Holtz, a leading authority on material handling systems, emphasizes the importance of selecting quality conveyor systems, stating, "Investing in stainless steel conveyors not only enhances productivity but also ensures compliance with health and safety regulations." This underscores the increasing significance of material quality and design in ensuring seamless operations while upholding industry standards. As businesses plan their conveyor system strategies for 2025, understanding the key attributes that define the best stainless steel conveyors will be essential for optimizing performance and achieving competitive advantages.

Understanding the Different Types of Stainless Steel Conveyors Available

When selecting the best stainless steel conveyors for your business, it is essential to understand the various types available on the market. The most common types include belt conveyors, roller conveyors, and modular conveyors, each designed to meet specific operational needs. According to a recent industry report by Grand View Research, the global conveyor systems market is expected to reach USD 8.2 billion by 2025, highlighting the increasing reliance on these systems across multiple sectors, including food processing, packaging, and manufacturing.

Belt conveyors are ideal for moving bulk materials and are widely used due to their flexibility and low maintenance costs. In contrast, roller conveyors offer enhanced durability and efficiency, especially in handling heavier loads. They are particularly valuable in warehouse settings, where item sorting and movement are crucial for operational efficiency. Modular conveyors provide businesses with customizable options, allowing them to adapt the conveyor design to specific spatial constraints, which is critical in optimizing production lines. According to a report from MarketsandMarkets, the modular conveyor systems market alone is projected to grow at a CAGR of 7.1% by 2024, reflecting the increasing demand for tailored solutions in logistics and manufacturing.

Understanding these types allows businesses to make informed decisions based on their unique requirements. Companies must evaluate factors such as load capacity, environmental conditions, and the specific materials being handled to choose the most suitable conveyor type for their operations. By considering these elements, businesses can enhance their operational efficiency and productivity across the board.

2025 How to Choose the Best Stainless Steel Conveyors for Your Business

| Conveyor Type | Material Grade | Load Capacity | Applications | Maintenance Level |

|---|---|---|---|---|

| Modular Belt Conveyor | 304 Stainless Steel | Up to 1000 kg | Food Processing | Low |

| Chain Driven Conveyor | 316 Stainless Steel | Up to 2000 kg | Automotive | Medium |

| Belt Conveyor | 304 Stainless Steel | Up to 1500 kg | Packaging | Low |

| Incline Conveyor | 304 Stainless Steel | Up to 800 kg | Food & Beverage | Medium |

| Roller Bed Conveyor | 316 Stainless Steel | Up to 1200 kg | Logistics | Low |

Key Factors to Consider When Selecting Stainless Steel Conveyors

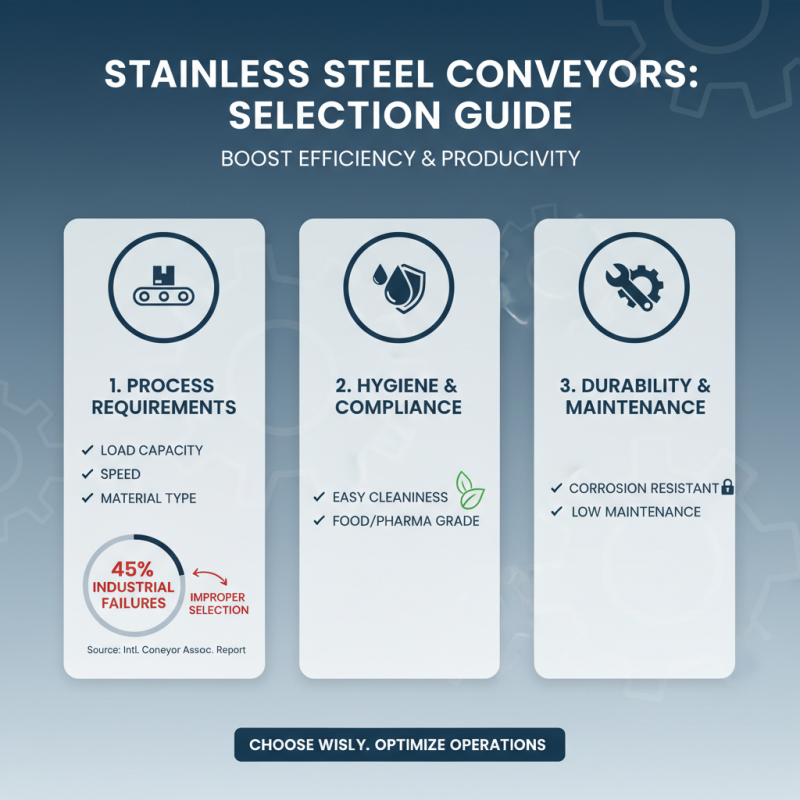

Choosing the best stainless steel conveyors for your business involves evaluating several key factors that can significantly impact efficiency and productivity. First and foremost, consider the specific requirements of your production process. According to a report by the International Conveyor Association, nearly 45% of industrial failures can be traced back to the improper selection of conveyor systems. Assess the load capacity, speed, and the type of materials being transported to ensure the conveyor meets your operational needs.

In addition to functional requirements, the environment where the conveyor will be used is crucial. Stainless steel is known for its corrosion resistance and hygiene, making it ideal for industries like food processing and pharmaceuticals. However, it's essential to understand the grade of stainless steel used, as different grades can withstand varying levels of exposure to chemicals and temperatures. A recent study indicated that using the right grade of stainless steel can enhance the longevity of conveyors by up to 30%, reducing maintenance costs significantly.

**Tips:** Always opt for conveyors that are easy to clean and maintain, especially in industries with strict sanitation requirements. Additionally, consulting industry experts or utilizing load simulation software can aid in selecting the best conveyor for your specific applications, ensuring you invest wisely in technology that will support your operational efficiency.

Evaluating the Durability and Maintenance Requirements of Conveyors

When selecting stainless steel conveyors for your business, evaluating durability and maintenance requirements is essential. According to a recent industry report, stainless steel conveyors can last up to 20 years or more with proper maintenance, outperforming alternative materials like plastic or fiberglass, which may have a significantly shorter lifespan. The main factors affecting durability include exposure to corrosive environments, load capacity, and the frequency of use. Using premium-grade stainless steel, such as 304 or 316, can significantly enhance the lifespan of your equipment, particularly in food processing and pharmaceutical applications where hygiene standards are critical.

Tip: To maximize the durability of your conveyors, implement a regular inspection schedule to check for wear and tear. Early detection of issues allows for timely repairs, thereby preventing further damage and costly downtime. Additionally, consider utilizing conveyor systems with modular designs that allow for easier maintenance and part replacement.

Maintenance practices also play a pivotal role in prolonging the life of your conveyance systems. Regular cleaning, lubrication, and alignment checks can prevent operational failures. A study found that businesses that adopt a proactive maintenance strategy experience 30% less equipment malfunction compared to those with reactive maintenance practices. Proper training of staff on handling and maintaining conveyors can further ensure their longevity.

Tip: Invest in training sessions for your operators that focus on best maintenance practices and the importance of adhering to manufacturer guidelines. This proactive approach can significantly reduce unexpected downtimes and enhance operational efficiency.

Comparing Costs and Budgeting for Stainless Steel Conveyor Systems

When considering the acquisition of stainless steel conveyor systems for your business, budgeting and understanding costs is crucial. The price of stainless steel conveyors can vary widely based on factors such as size, design, load capacity, and intended application. Basic models might be more affordable, but customizing conveyor systems with specific features or enhanced durability may significantly increase the total investment. Businesses should conduct a thorough cost analysis, taking into account not only the initial purchase price but also long-term operational costs, including maintenance, energy consumption, and potential downtime.

Assessing the total cost of ownership is essential when budgeting for stainless steel conveyor systems. This includes evaluating warranty options, potential repair costs, and the availability of replacement parts. Additionally, integrating conveyors into existing production lines may involve extra expenses, such as installation or modification costs, which should be factored into the overall budget. By having a clear understanding of both the upfront and ongoing costs, businesses can make informed decisions, ensuring that the conveyor systems they choose will meet their operational needs without compromising financial stability. Properly balancing these financial considerations will lead to a more strategic investment in efficient and effective material handling solutions.

Identifying the Best Suppliers and Manufacturers for Your Needs

When selecting the best suppliers and manufacturers for stainless steel conveyors, it's essential to consider several key factors that align with the specific needs of your business. Firstly, evaluate the supplier’s experience and expertise in the industry. According to a recent report by the Material Handling Industry (MHI), businesses that collaborate with manufacturers who have over a decade of experience tend to report up to 30% higher satisfaction rates regarding product reliability and performance. This depth of experience often translates into better understanding of industry standards, compliance, and innovation, ensuring that the products meet specific operational requirements.

Additionally, it is crucial to assess the supplier's ability to provide customization options for stainless steel conveyors. A survey conducted by Industrial Equipment News found that 65% of companies prefer suppliers that offer tailored solutions to suit unique operational processes. This flexibility allows businesses to optimize their conveyor systems for efficiency and productivity, ultimately impacting their bottom line. Furthermore, consider the supplier's certifications and quality assurance processes, as these factors are critical in the production of stainless steel equipment that can withstand rigorous use and meet hygienic standards in industries such as food processing and pharmaceuticals. Engaging with suppliers that prioritize quality and offer transparent communication can significantly enhance your procurement strategy.

2025 Stainless Steel Conveyors Comparison

This chart represents the weight capacity (in kg) of different types of stainless steel conveyors, which helps businesses identify the best options for their needs.

Related Posts

-

What is an Industrial Meat Grinder Machine and How to Choose the Best One

-

How to Choose the Right Food Manufacturing Equipment for Your Business Needs

-

Top 10 Commercial Meat Blenders for Perfectly Ground Meat Every Time

-

Top 10 Belt Conveyor Design Tips for Efficient Material Handling

-

7 Best Metal Detectors for Conveyor Belts to Ensure Quality Control in 2023

-

The Ultimate Guide to Dog Food Manufacturing Equipment in 2025 Top Trends