Top 10 Essential Screw Conveyor Parts You Need to Know for Optimal Performance

In the world of material handling, understanding the intricacies of screw conveyor parts is crucial for ensuring optimal performance and efficiency. According to industry expert John Smith, a recognized authority in the design and operation of bulk handling systems, "The right components not only enhance the productivity of a screw conveyor but also significantly reduce maintenance costs." This insight underscores the importance of knowing which screw conveyor parts are essential for a well-functioning system.

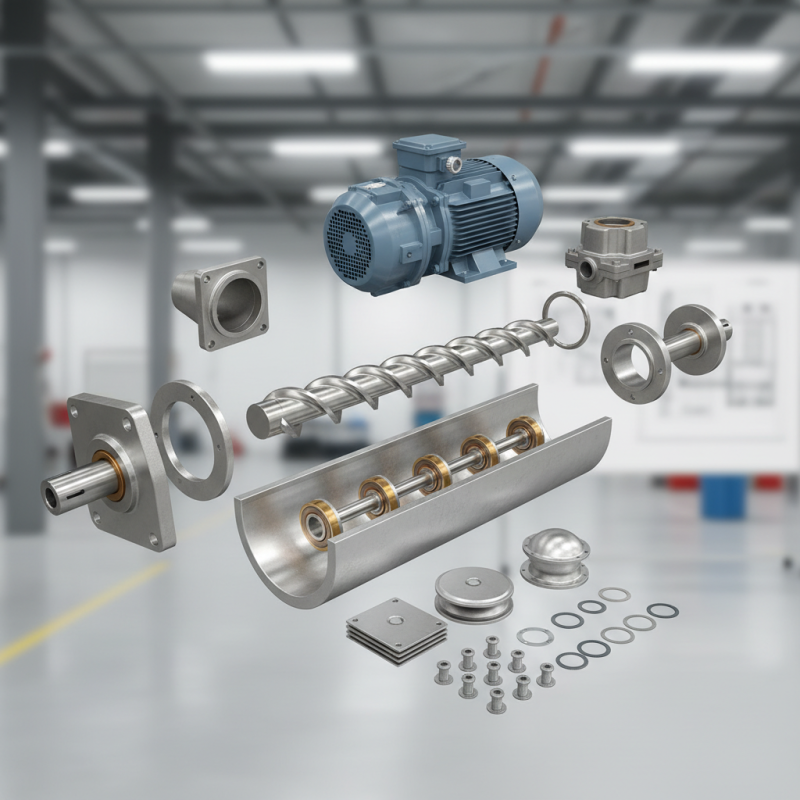

When it comes to screw conveyors, each component—from the screw flights to the drive mechanism—plays a vital role in the overall effectiveness of the operation. A comprehensive understanding of these parts allows operators and engineers to troubleshoot effectively and optimize performance. As industries continue to evolve, the need for reliable and efficient screw conveyor systems remains paramount, making knowledge of these critical components more valuable than ever. By focusing on the top ten essential screw conveyor parts, stakeholders can ensure that their systems are not only running smoothly but also sustainably, adapting to the changing demands of material handling.

Understanding the Function of Screw Conveyors in Material Handling

Screw conveyors are fundamental components in the field of material handling, primarily used for the efficient transport of bulk materials. Their design incorporates a helical screw blade, which rotates within a cylindrical casing to move material from one point to another. This efficiency stems from the ability to handle a wide range of materials, from powders and granules to more cohesive substances, facilitating a seamless flow in various industrial applications.

Understanding the function of screw conveyors begins with recognizing their versatility and adaptability. They can be configured for horizontal, inclined, or vertical transport, making them suitable for different layouts and workspace constraints. The design and construction of the conveyor allow for adjustments in speed and flow, ensuring optimal performance tailored to specific material characteristics. Additionally, screw conveyors can be equipped with various features, such as trough liners and segmented screws, which enhance their durability and effectiveness in maintaining material integrity during handling.

Key Components of a Screw Conveyor and Their Roles

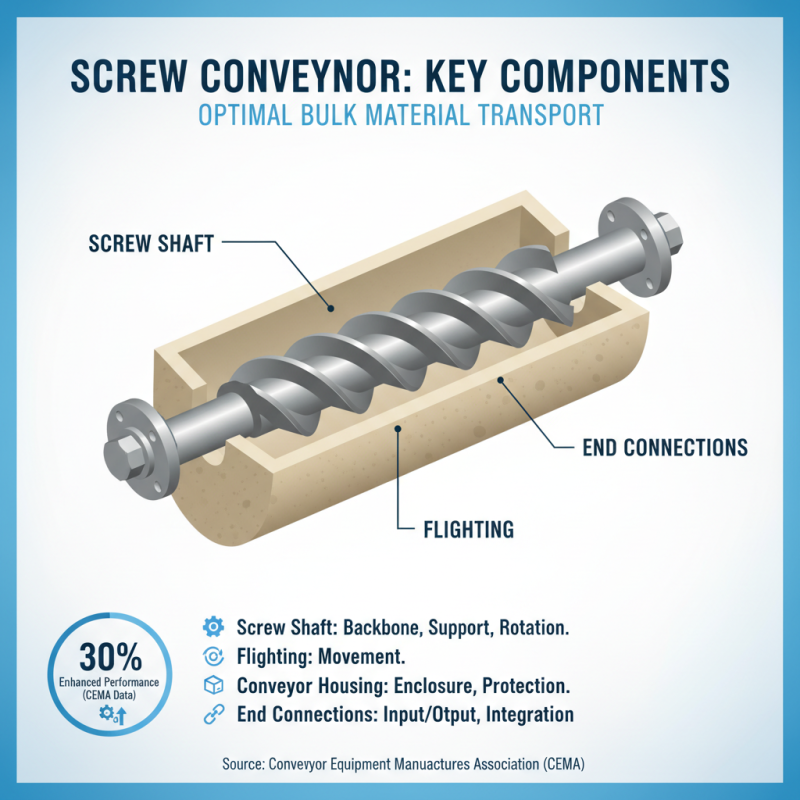

Screw conveyors are crucial in various industries for the efficient transport of bulk materials. Understanding the key components of a screw conveyor is essential for ensuring optimal performance and longevity. The primary elements include the screw shaft, flighting, conveyor housing, and end connections. The screw shaft serves as the backbone of the conveyor, providing the necessary support and rotating capability for material movement. Data from the Conveyor Equipment Manufacturers Association (CEMA) indicates that the proper design and material selection for the screw shaft can enhance performance by up to 30%, minimizing wear and tear in high-load applications.

Flighting, typically made from durable materials like carbon steel or stainless steel, determines the efficiency of material transportation. The pitch and thickness of the flighting directly affect the volume of material being moved; accordingly, calculating the correct specifications is vital. Research highlights that adjusting flight dimensions can lead to energy savings of up to 25% in energy-intensive operations. The conveyor housing encases the screw, playing a significant role in protecting against external contaminants and facilitating controlled material flow. Understanding how these components work together allows for better design decisions, ultimately enhancing the operational efficiency and reliability of screw conveyors in an array of settings from food processing to construction.

Essential Features of a Screw Conveyor Screw Flight

The screw flight, an integral component of screw conveyors, plays a pivotal role in material handling efficiency. The design of the screw flight directly influences the performance parameters, including material flow rate, conveying distance, and energy consumption. According to industry reports, optimizing screw flight design can improve throughput by up to 30%, significantly reducing operational costs and enhancing overall system reliability.

When considering the essential features of a screw flight, several factors need to be accounted for. The pitch, or the distance between consecutive flights, affects the space through which the materials pass. A shorter pitch may increase the material retention time, making it ideal for bulk materials that require thorough mixing or dewatering. Additionally, the thickness of the flight impacts wear resistance, as thicker flights withstand abrasion from coarse materials, prolonging the lifespan of the conveyor system. Data from the Conveying Equipment Manufacturers Association highlights that wear costs can be reduced by as much as 25% with appropriately designed flights tailored to the specific materials being handled.

Furthermore, the shape of the screw flight itself can lead to more effective material handling. For instance, a tapered flight can facilitate smoother material flow and reduce the energy required to drive the conveyor, an important consideration considering that energy costs account for a significant portion of operational expenses. Collectively, tailoring the screw flight design and configuration based on these essential features not only maximizes performance but also enhances operational efficiency across various industries.

Top 10 Essential Screw Conveyor Parts You Need to Know for Optimal Performance

The Importance of Bearing Support in Screw Conveyor Operation

In the operation of screw conveyors, bearing support plays a critical role in ensuring optimal performance and longevity. Bearings are essential components that maintain the alignment and stability of the rotating screw shaft. According to the Conveyor Equipment Manufacturers Association (CEMA), proper bearing maintenance can reduce operational failures by as much as 30%. When bearings are correctly installed and adequately lubricated, they can withstand the considerable stresses experienced during material conveyance, which reduces wear and enhances the efficiency of the conveyor system.

Moreover, bearing support contributes significantly to the overall energy efficiency of screw conveyors. A study by the Association of American Railroads found that the efficient functioning of bearings can lower energy costs by up to 15%. This is largely due to the reduction in friction between moving parts, which not only enhances performance but also minimizes unnecessary strain on the motor and drives.

Additionally, choosing the right type of bearings tailored to the specific material and operating conditions can drastically enhance the lifespan of the screw conveyor. Proper bearing selection, combined with routine maintenance, is thus paramount in optimizing not just the operation but the reliability of screw conveyor systems.

Maintenance Tips for Improving Screw Conveyor Performance

To ensure optimal performance of screw conveyors, regular maintenance is crucial. According to the Conveyor Equipment Manufacturers Association (CEMA), approximately 30% of screw conveyor failures can be attributed to inadequate maintenance practices. One of the key maintenance strategies is to conduct routine inspections of wear components, such as the flight and casing. Early identification of wear can prevent significant downtime and costly repairs, optimizing the operational efficiency of the conveyor system.

In addition to regular inspections, effective lubrication plays a vital role in maintaining screw conveyor performance. A well-lubricated system can enhance the lifespan of critical components by reducing friction and wear. Research indicates that proper lubrication can improve energy efficiency by up to 20%, resulting in cost savings and enhanced productivity. Moreover, operators should monitor for material buildup, as this can lead to blockages and inefficient operations. Implementing cleaning procedures in conjunction with maintenance checks will further ensure the longevity and reliability of screw conveyors, ultimately supporting a smoother production process.

Top 10 Essential Screw Conveyor Parts You Need to Know for Optimal Performance

| Part Name | Material | Function | Maintenance Tips |

|---|---|---|---|

| Screw Blade | Carbon Steel | Moves material along the conveyor | Regularly check for wear and tear; replace when necessary |

| Housing | Stainless Steel | Encloses the screw and protects it from damage | Inspect for corrosion; clean regularly |

| End Bearings | Bronze | Supports the screw shafts | Lubricate periodically; check alignment |

| U-Joint | Steel | Allows for angular movement between shafts | Check for lubrication; replace if noisy |

| Motor | Aluminium | Drives the screw conveyor | Monitor for overheating; ensure proper voltage |

| Hopper | Steel | Holds material before moving | Clean to prevent blockages |

| Discharge Spout | Plastic | Directs material to its destination | Inspect for cracks; replace as needed |

| Wear Liners | Polyurethane | Protects housing from wear | Replace when worn down |

| Safety Switch | Plastic | Prevents operation in unsafe conditions | Test functionality regularly |

| Control Panel | Metal | Central hub for operating the conveyor | Ensure switches and indicators function |

Related Posts

-

What is an Industrial Meat Grinder Machine and How to Choose the Best One

-

Top 10 Commercial Meat Blenders for Perfectly Ground Meat Every Time

-

How to Choose the Right Dog Food Manufacturing Equipment for Your Business

-

What is Dog Food Manufacturing Equipment? Essential Tools for Pet Food Production

-

The Ultimate Guide to Dog Food Manufacturing Equipment in 2025 Top Trends

-

10 Essential Tips for Choosing the Right Conveyor Belt Conveyor for Your Business