Top 10 Benefits of Using Metal Belt Conveyors in Modern Industries?

In today's fast-paced industrial landscape, efficiency is paramount. The use of metal belt conveyors has surged, driven by their rugged durability and versatility. According to a recent report by the Conveyor Equipment Manufacturers Association (CEMA), metal belt conveyors can streamline production processes and enhance safety. These systems often outperform traditional conveyors, especially in handling heavy and abrasive materials.

John Smith, an industry expert and consultant at Conveyor Solutions, notes, "Metal belt conveyors provide unmatched reliability in demanding environments." This technology is not without its challenges. Maintenance can be complex, and upfront costs may deter some businesses. However, the long-term benefits frequently outweigh these initial hurdles.

As industries evolve, the need for robust and efficient conveying systems is clear. Metal belt conveyors are increasingly recognized for their ability to adapt across various applications. Industries from automotive to food processing are experiencing significant improvements in production flow. Such advancements speak to the critical role of metal belt conveyors in modern manufacturing.

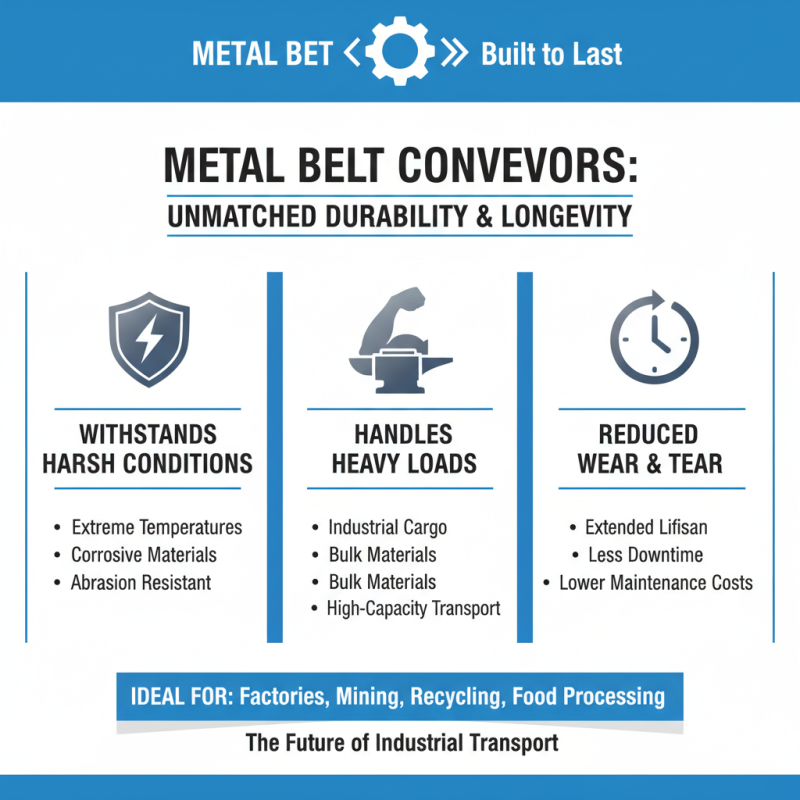

Benefits of Durability and Longevity of Metal Belt Conveyors

Metal belt conveyors are known for their impressive durability and longevity. Unlike traditional conveyors, they withstand harsh conditions. These belts often handle heavy loads and resist wear and tear. This resilience means they can operate in various environments, from factories to mining sites.

Using metal for belt construction allows for higher temperature resistance. This feature is crucial in industries that deal with heat-sensitive materials. Moreover, metal belts are less prone to damage from chemicals or abrasion. Industries often face challenges due to equipment failures. Metal belts reduce these failures, saving money over time.

Regular maintenance is essential, even for durable systems. Some users find it challenging to address minor wear before it escalates. The long lifespan of metal conveyors may lead to complacency. Yet, keeping a close eye on the belts ensures their optimal performance. Avoiding neglect is vital to maintain their benefits.

Efficiency in Material Handling with Metal Belt Conveyors

Metal belt conveyors play a vital role in modern industries, significantly enhancing efficiency in material handling. These conveyors utilize durable metal belts that resist wear and tear, making them ideal for heavy loads. They easily transport materials across various distances, which saves time and labor costs. Industries like automotive and food processing particularly benefit from their robust structure.

The seamless design of metal belt conveyors minimizes the risk of product damage. This is crucial when moving fragile items, ensuring safety throughout the process. Additionally, their versatility allows for customization to fit specific production needs. However, maintenance can become an issue if not properly monitored. Regular checks are necessary to avoid unexpected downtimes.

High temperatures or harsh chemicals can pose challenges for metal belts. Careful consideration of the working environment is essential. Thankfully, their strength often compensates for these factors, making them a preferred choice in many sectors. Companies must continuously evaluate their conveyor systems. Identifying potential areas for improvement can lead to even greater efficiency.

Top 10 Benefits of Using Metal Belt Conveyors in Modern Industries

Enhanced Safety Features in Metal Belt Conveyor Systems

Metal belt conveyor systems are gaining popularity in modern industries due to their enhanced safety features. These systems are designed to minimize workplace accidents by incorporating safety guards, emergency stop buttons, and sensor technology. A study from the National Safety Council indicates that injuries related to conveyor systems account for a significant percentage of workplace incidents. By using metal belt conveyors, companies can significantly reduce these risks.

Moreover, the durability and strength of metal belts contribute to safer operations. Unlike plastic or rubber, metal belts can withstand harsh conditions. This robustness reduces the chances of malfunction and potential hazards. According to industry surveys, about 70% of businesses report improved safety records after implementing these systems. Nonetheless, proper maintenance is crucial. Regular inspections and timely repairs can prevent unexpected breakdowns. A lack of attention to these maintenance needs can lead to system failures, causing injuries or damage.

Additionally, metal belt conveyors offer seamless integration with advanced safety devices. Features like load sensors and automatic shut-off systems enhance their functionality. These measures ensure that operations halt immediately in case of any anomaly. However, employee training is essential. Workers need to understand how to operate these systems safely. Without adequate training, even the best safety features can falter.

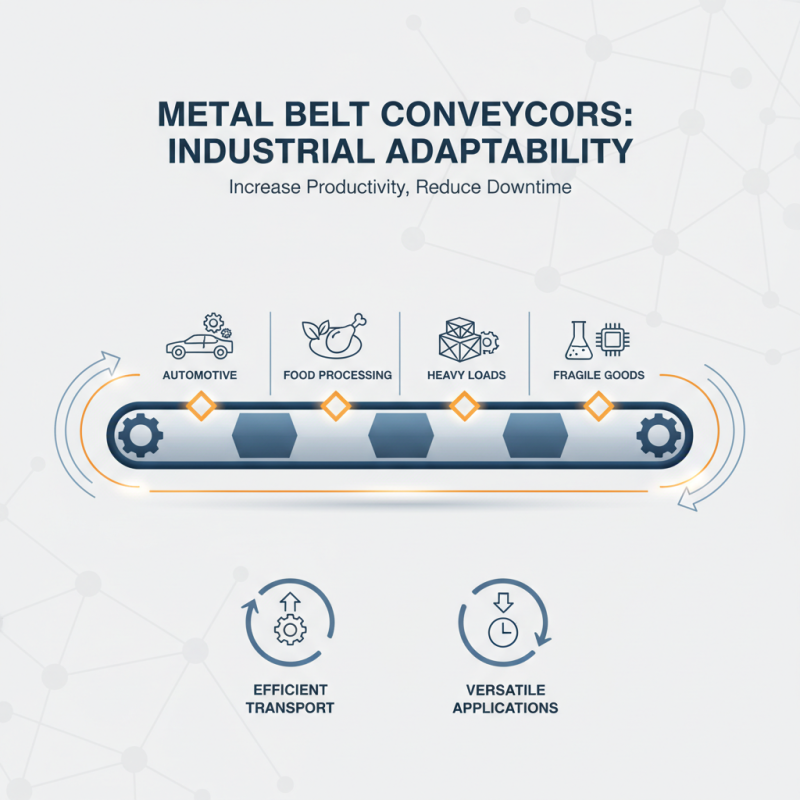

Versatility of Metal Belt Conveyors Across Various Industries

Metal belt conveyors play a crucial role in modern industries. Their versatility allows them to adapt to various applications. From automotive to food processing, these conveyors handle a range of materials. They are efficient for transporting heavy items and fragile products alike. This adaptability increases productivity and minimizes downtime during operations.

In the automotive industry, for example, metal belt conveyors transport parts through assembly lines. They withstand demanding environments and resist heat and wear. In food production, they maintain hygiene standards and are easy to clean. However, choosing the correct conveyor for each application is not always straightforward.

While metal belt conveyors excel in many areas, they can also present challenges. They might require special maintenance or adjustments for optimal performance. Industries must evaluate their specific needs to avoid costly mistakes. Careful consideration of material types and production processes can lead to better outcomes. Exploring these options may reveal innovative solutions for unique challenges.

Reduced Maintenance Costs Associated with Metal Belt Conveyors

Metal belt conveyors offer a significant advantage in terms of reduced maintenance costs. Their robust construction ensures longevity. Unlike plastic belts, metal belts are less susceptible to wear and tear. This durability translates to fewer breakdowns, saving both time and money for businesses.

Routine maintenance is straightforward. Technicians find it easier to inspect and replace parts as needed. Metal belts do not require extensive lubrication systems. This simplicity reduces the complexity of maintenance schedules. Many users report spending less time on repairs, which allows for more focus on productivity.

However, it's important to consider initial setup costs. Metal belts can be more expensive upfront. Yet, the long-term savings often outweigh this initial investment. Some companies might hesitate because of this cost. Assessing the overall benefits allows for a clearer perspective on the value of metal belt conveyors in the manufacturing process.

Related Posts

-

10 Essential Tips for Choosing the Right Conveyor Belt Conveyor for Your Business

-

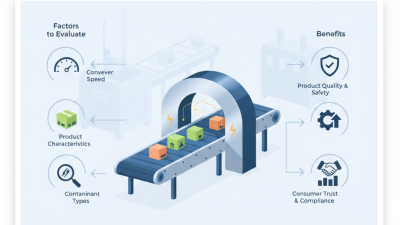

How to Choose the Right Metal Detector for Your Conveyor Belt System

-

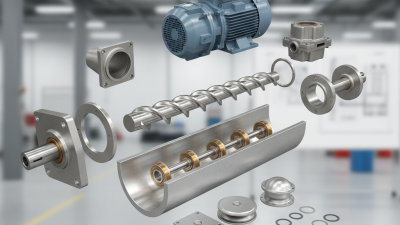

Top 10 Essential Screw Conveyor Parts You Need to Know for Optimal Performance

-

7 Best Metal Detectors for Conveyor Belts to Ensure Quality Control in 2023

-

Top 10 Belt Conveyors Trends to Watch in 2025 for Efficient Material Handling

-

2025 How to Choose the Right Screw Conveyor Auger for Your Needs