Why Are Belt Conveyor Systems Essential for Modern Manufacturing Efficiency

In the rapidly evolving landscape of modern manufacturing, the efficiency of production processes is paramount. Belt conveyor systems have emerged as a cornerstone of operational effectiveness, streamlining workflows and enhancing productivity across various industries. According to Dr. Emily Hartman, a leading expert in industrial automation, "Belt conveyor systems are not just a logistics tool; they are integral to optimizing the entire manufacturing process, allowing for seamless transition of materials and reduced downtime."

The significance of belt conveyor systems extends beyond mere transportation; they play a crucial role in ensuring that manufacturing processes are agile and adaptable. As industries strive for higher output and improved quality, the implementation of advanced conveyor technologies becomes essential. These systems facilitate the automation of tasks, reduce manual handling, and ultimately support the creation of a more efficient production environment.

Moreover, the strategic use of belt conveyor systems can lead to substantial cost savings and enhanced safety measures within the workplace. By minimizing the need for labor-intensive material handling and reducing the risk of workplace injuries, manufacturers can focus on innovation and quality assurance. As the industry continues to advance, the role of belt conveyor systems will undoubtedly remain pivotal in driving efficiency and competitiveness in the global market.

The Role of Belt Conveyor Systems in Modern Manufacturing

Belt conveyor systems play a crucial role in modern manufacturing by streamlining operations and enhancing overall productivity. These systems are designed to transport materials efficiently across various stages of the production process, reducing the need for manual handling and minimizing the risk of errors. By automating the movement of goods, manufacturers can significantly cut down on labor costs and time delays, allowing for a smoother workflow and faster turnaround times.

In addition to improving efficiency, belt conveyor systems also contribute to safety in the manufacturing environment. They help minimize the hazards associated with manual lifting and transporting heavy materials, leading to a decrease in workplace injuries. Furthermore, these systems can be customized to accommodate different types of products and production layouts, making them adaptable to various manufacturing needs. Ultimately, the integration of belt conveyor systems into production lines not only boosts efficiency but also fosters a safer and more organized work environment.

Key Benefits of Implementing Belt Conveyor Systems

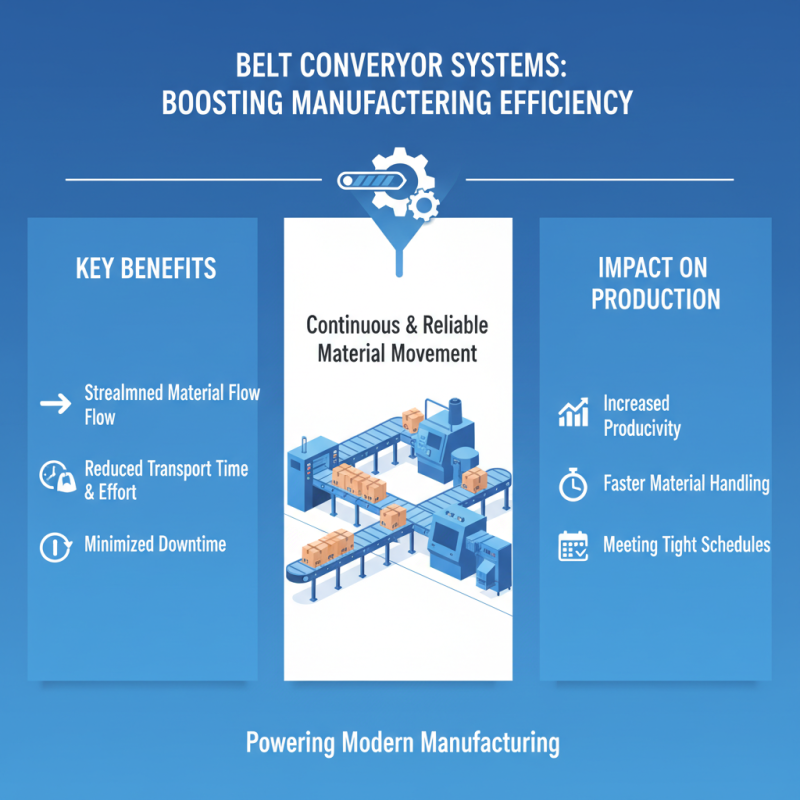

Belt conveyor systems play a pivotal role in enhancing manufacturing efficiency by streamlining the movement of materials. One of the key benefits of these systems is their ability to significantly reduce the time and effort required for transporting materials between different production stages. By utilizing a continuous and reliable conveyor mechanism, manufacturers can maintain a steady flow of materials, minimizing downtime and increasing overall productivity. This is especially advantageous in environments where rapid material handling is crucial to meeting tight production schedules.

Additionally, belt conveyor systems contribute to improved safety and ergonomics in the workplace. By automatically carrying heavy or bulky items, these systems help reduce the physical strain on workers, lowering the risk of injuries associated with manual handling. Moreover, the consistent and predictable nature of belt conveyors reduces the likelihood of accidents caused by unexpected movement or manual mishandling of materials. This fosters a safer working environment and allows employees to focus on more skilled tasks, further enhancing workplace efficiency and operational effectiveness.

Types of Belt Conveyor Systems Used in Manufacturing

Belt conveyor systems are vital components in modern manufacturing facilities, streamlining operations and enhancing efficiency. Various types of belt conveyor systems are employed to cater to the diverse needs of the manufacturing sector. The most common types include flat belt conveyors, modular belt conveyors, and cleated belt conveyors. Flat belt conveyors are favored for their versatility and are used for transporting a wide range of materials, from small packages to heavy pallets. According to the Conveyor Equipment Manufacturers Association (CEMA), flat belt systems are considered a staple, accounting for approximately 40% of the conveyor market.

Modular belt conveyors offer the benefit of easy maintenance and adaptability to complex layouts. Utilized primarily in industries requiring high sanitation standards, such as food processing and pharmaceuticals, these systems can handle various product sizes and shapes. A recent industry report highlighted that modular belts could reduce downtime by up to 35% due to their ability to be quickly replaced and reconfigured without major disruption to the production process.

Cleated belt conveyors are specialized for transporting products at an incline or during the sorting process. These systems are designed with raised edges or partitions that help maintain product position, making them ideal for handling bulk materials like grains or powder. By providing improved product flow and minimizing spillage, cleated belts can enhance operational efficiency and reduce waste, contributing to an estimated 20% increase in throughput for many manufacturers. The growing adoption of these various belt conveyor systems reflects an industry's shift towards automation and optimized productivity.

Impact of Belt Conveyor Systems on Production Efficiency

Belt conveyor systems play a pivotal role in boosting production efficiency across modern manufacturing environments. By providing a seamless, continuous flow of materials, these systems significantly reduce the time taken to transport components from one stage of the production process to another. This not only expedites workflow but also minimizes the likelihood of bottlenecks that can disrupt operations. Consequently, manufacturers can maintain a steady pace of output, allowing for increased volume and better meeting customer demands.

Moreover, the integration of belt conveyor systems enhances the overall organization of the production floor. With materials systematically routed along designated paths, it becomes easier to manage inventory and streamline processes. This organized flow of materials ensures that employees can focus more on value-added tasks rather than manual transportation, leading to higher productivity levels. Additionally, the versatility of belt conveyors allows them to handle various types of materials, making them an indispensable component in diverse manufacturing settings. By optimizing both time and space, these systems fundamentally reshape the efficiency landscape of modern manufacturing.

Future Trends in Belt Conveyor Technology for Enhanced Performance

The future of belt conveyor technology is poised for significant advancements that will enhance performance and efficiency in modern manufacturing. One of the key trends is the integration of smart technologies, such as IoT (Internet of Things) sensors, which enable real-time monitoring of conveyor systems. This capability allows manufacturers to track operational metrics such as speed, load weight, and maintenance needs, facilitating predictive maintenance and minimizing downtime. The use of machine learning algorithms can further optimize the conveyor's performance by analyzing data patterns to provide insights for improved operational practices.

Another emerging trend in belt conveyor technology is the development of eco-friendly materials and designs. As sustainability becomes a priority for many industries, manufacturers are seeking ways to reduce their carbon footprint. Innovations such as lightweight synthetic belts and energy-efficient motors are being implemented to decrease energy consumption. Additionally, systems that incorporate modular components allow for easier upgrades and repairs, extending the life cycle of the equipment while reducing waste. These advancements not only enhance the reliability and effectiveness of conveyor systems but also align with broader environmental goals in manufacturing.

Future Trends in Belt Conveyor Technology for Enhanced Performance

Related Posts

-

10 Essential Tips for Choosing the Right Conveyor Belt Conveyor for Your Business

-

How to Choose the Right Food Manufacturing Equipment for Your Business Needs

-

Top 10 Belt Conveyor Design Tips for Efficient Material Handling

-

Top 10 Commercial Meat Blenders for Perfectly Ground Meat Every Time

-

2025 Top Commercial Meat Grinders with Industry Leading Performance and Durability

-

What is an Industrial Meat Grinder Machine and How to Choose the Best One