Top 10 Belt Conveyor Design Tips for Efficient Material Handling

In the realm of material handling, the efficiency of operations is paramount. One of the pivotal components in this sector is the belt conveyor system, which plays a crucial role in transporting materials across various industries. According to the Conveyor Equipment Manufacturers Association (CEMA), belt conveyors account for approximately 30% of material transportation systems in manufacturing. With the burgeoning growth of e-commerce and manufacturing sectors, optimizing belt conveyor design has become more critical than ever.

Effective belt conveyor design not only enhances operational efficiency but also significantly reduces downtime and maintenance costs. A study published by the American Society of Mechanical Engineers (ASME) indicates that an optimized conveyor system can improve productivity by up to 25%. Furthermore, advancements in technology allow for smarter and more adaptable belt conveyor designs that can meet the evolving demands of modern industries. By focusing on the best design practices, companies can ensure that their belt conveyor systems align with the latest safety standards and performance benchmarks, ultimately driving a more efficient and sustainable material handling process.

Key Principles of Belt Conveyor Design for Material Handling

When designing a Belt Conveyor for efficient material handling, it is essential to adhere to key principles that maximize both functionality and safety. One fundamental principle is to ensure that the conveyor's layout aligns with the workflow. This means designing the system to accommodate the specific path of the materials, minimizing unnecessary turns and inclines, which can slow down operations and increase wear on the belt.

Another critical aspect is selecting the right belt material and width for the types of materials being handled. The belt should be durable enough to withstand the weight and abrasiveness of the materials, while also being wide enough to prevent spillage and ensure a consistent flow.

Additionally, it's important to consider proper tensioning and alignment of the belt to reduce the risk of slippage and maintenance downtime, creating a smoother and more efficient operational process. These principles contribute not only to the efficiency of material handling but also to the longevity of the conveyor system.

Selecting the Right Belt Material for Specific Applications

When designing an efficient belt conveyor system, selecting the right belt material is crucial for optimizing performance and ensuring longevity. Different applications require distinct properties from the belt material. For instance, lightweight materials like PVC are often suitable for handling lighter goods, while more robust options such as rubber are necessary for heavy-duty operations. Understanding the specific needs of the material being transported, such as temperature and chemical exposure, can greatly influence the choice of belt.

In addition to weight and durability, surface characteristics of the belt material play an essential role in operational efficiency. Textured surfaces can facilitate grip and reduce slippage when transporting items, while smooth surfaces may be more appropriate for items that require minimal friction. Furthermore, factors like abrasion resistance, flexibility, and resistance to oils or chemicals should be considered based on the environment and materials handled. A thorough evaluation of these aspects will not only enhance the conveyor's effectiveness but also contribute to a more sustainable material handling process.

Top 10 Belt Conveyor Design Tips for Efficient Material Handling

This chart illustrates the importance level of various design tips for belt conveyors in material handling applications. Each feature is rated on a scale from 1 to 10, where a higher number indicates greater importance in ensuring efficiency and effectiveness in material handling.

Importance of Proper Belt Speed and Load Capacity

When designing belt conveyors, understanding the importance of proper belt speed and load capacity cannot be overstated. According to a report by the Conveyor Equipment Manufacturers Association (CEMA), selecting the right belt speed is crucial because it directly affects the efficiency and safety of material handling processes. Optimal belt speeds generally range from 1.5 to 5 meters per second, depending on the material type and the conveyor system. Speeds that are too high can lead to increased wear and tear on both the conveyor and the material itself, while speeds that are too low can result in delays and decreased productivity.

To ensure efficient material handling, it’s essential to evaluate the load capacity requirements. Studies have shown that conveyors operating at or near their maximum load capacity are more prone to breakdowns and maintenance issues. It’s advisable to design for a load capacity that exceeds normal expectations by 20-30%. This not only extends the lifespan of the conveyor but also enhances its reliability.

Tip: Regularly monitor and adjust the belt speed based on material flow and conditions to optimize performance.

Tip: Conduct routine assessments to confirm that the load capacity is adequate for changes in material size or weight, preventing potential overload situations.

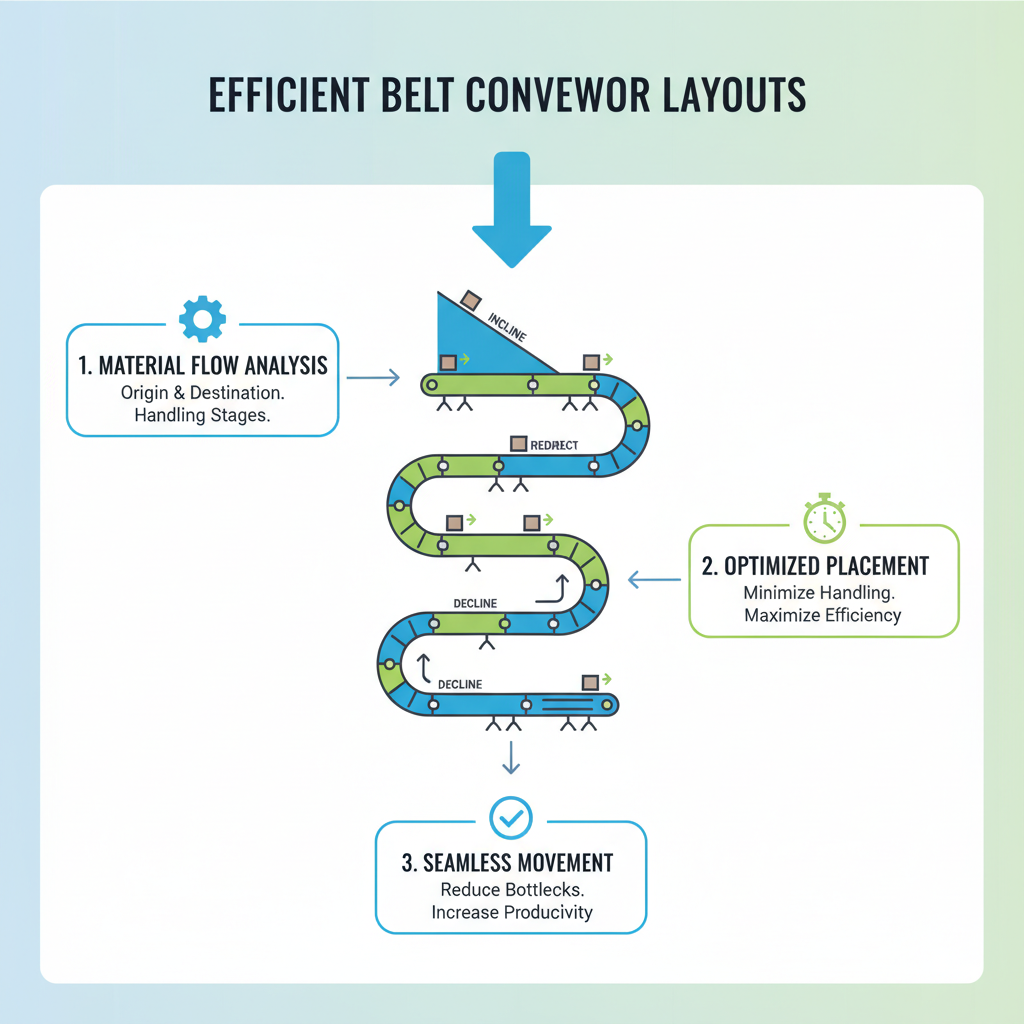

Designing Efficient Belt Conveyor Layouts and Configurations

When designing efficient belt conveyor layouts and configurations, the first consideration should be the flow of materials. This involves understanding the origin and destination of materials, as well as the various handling stages they will go through. A well-thought-out layout minimizes unnecessary handling and maximizes efficiency by strategically placing conveyors to create a seamless flow. Incorporating inclines, declines, and redirects ensures that materials can be moved swiftly and without obstruction, reducing bottlenecks and increasing productivity.

Another crucial aspect of conveyor design is the selection of the appropriate conveyor type and configuration based on the material being transported. For instance, using a modular belt for irregular items allows for more flexibility and easier maintenance. Additionally, ensuring that the conveyor's width, speed, and load capacity align with the operational requirements prevents potential overloads and ensures longevity. Adequate spacing and structural support are essential in preventing wear and tear, while also facilitating service access. By prioritizing these factors, companies can create optimized belt conveyor systems that enhance overall material handling efficiency.

Maintenance Tips for Optimal Belt Conveyor Performance

Effective maintenance is crucial for ensuring optimal belt conveyor performance, as these systems often represent significant investment in material handling operations. According to the International Journal of Mechanical Engineering, proper maintenance can improve conveyor efficiency by up to 40%. Regular inspections, lubrication of moving parts, and timely replacement of worn components can minimize downtime and extend the lifespan of the equipment.

Furthermore, adopting a predictive maintenance strategy can be highly beneficial. A 2022 report by the Conveyor Equipment Manufacturers Association (CEMA) indicates that predictive maintenance can reduce unexpected failures by 70%, ensuring that conveyors operate at peak performance. Implementing advanced monitoring technologies, such as sensors and data analytics, allows operators to foresee potential issues before they escalate, optimizing maintenance schedules and resource allocation. This proactive approach not only enhances productivity but also significantly contributes to cost savings in the long run.

Related Posts

-

How to Choose the Right Food Manufacturing Equipment for Your Business Needs

-

7 Best Metal Detectors for Conveyor Belts to Ensure Quality Control in 2023

-

What is an Industrial Meat Grinder Machine and How to Choose the Best One

-

2025 Top Commercial Meat Grinders with Industry Leading Performance and Durability

-

10 Essential Tips for Choosing the Right Conveyor Belt Conveyor for Your Business

-

Top 10 Commercial Meat Blenders for Perfectly Ground Meat Every Time